17 Jan, 2019

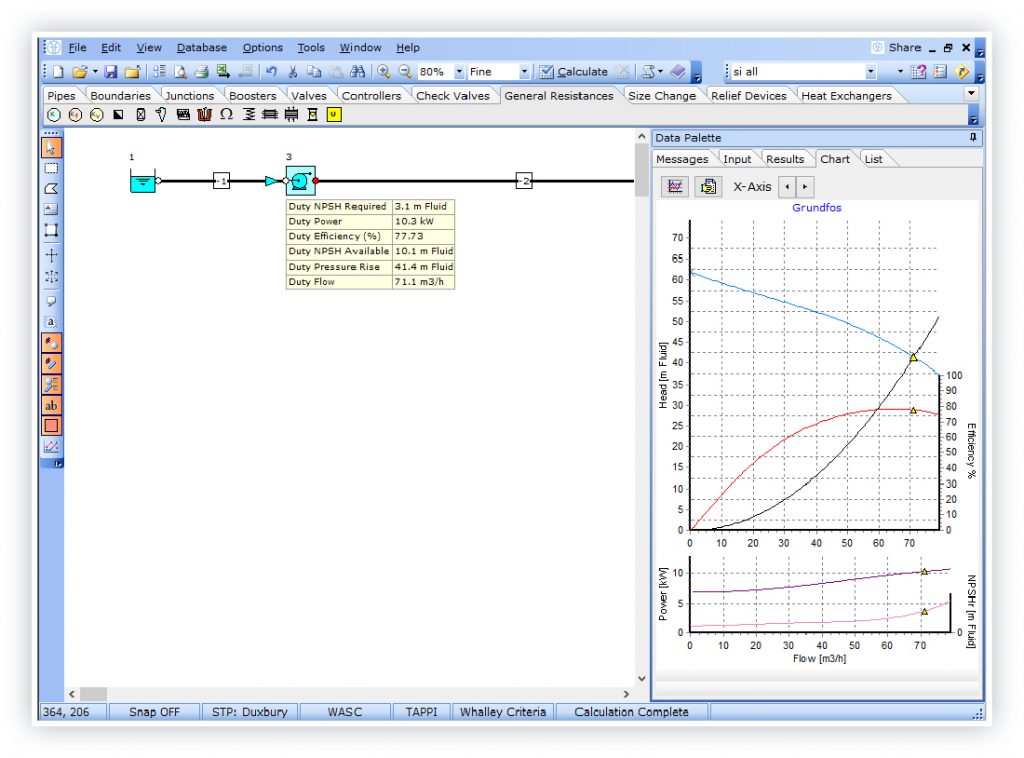

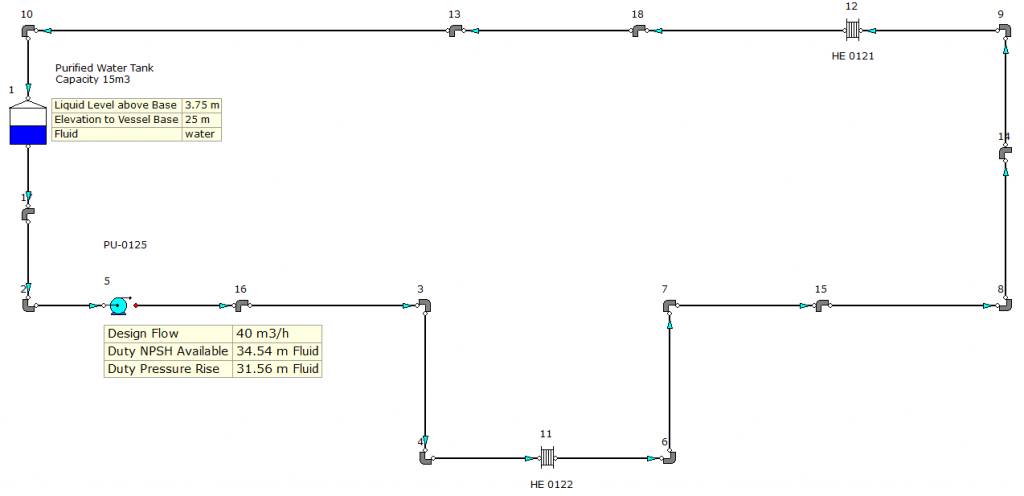

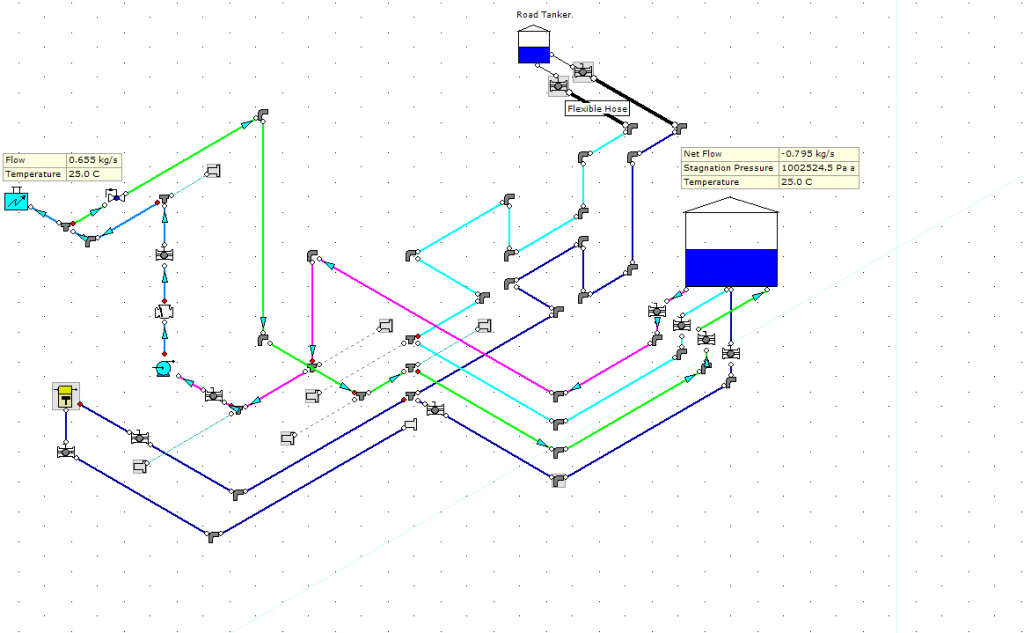

Liquids,

Incompressible Flow

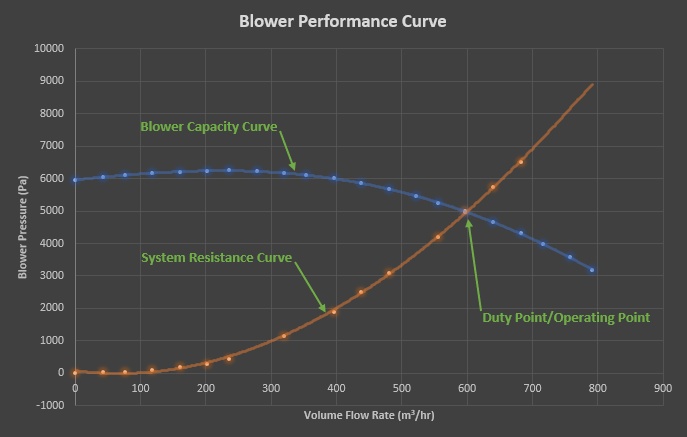

- Delivers fast and accurate designs for Newtonian fluids.

- Determines system operating pressures, flow distribution and fluid physical properties.

- Allows for the modeling of a wide range of line equipment items.