Gas Flow

Simulation Software

Compressible flow made practical. Model operating conditions, reduce losses, and optimize design for gas and vapor systems.

Core Gas Flow Capabilities

Precise Computational Modeling for Gas Flow Systems

Why Engineers Choose FluidFlow

FluidFlow’s compressible flow simulation easily models gas systems and analyzes pipeline operating conditions.

Economic Pipe Sizing Using the Generaux Equation

Optimize pipe diameter by evaluating both upfront cost and lifetime energy consumption.

Accurate Pressure Loss

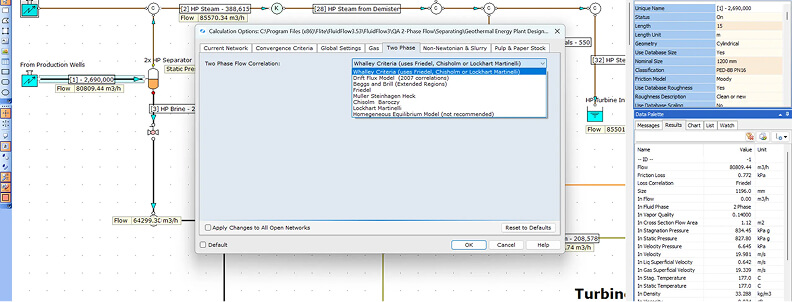

Compute pressure loss using conservation equations and EOS (e.g., Benedict–Webb–Rubin, Peng–Robinson, Lee–Kesler), including Joule–Thomson effects to account for temperature changes.

Clear Visualization of System Behavior

See pressures, temperatures, velocities, and demand response across the network under changing operating loads.

Industry-Specific Applications

Power Generation

Application

Key Capabilities

Oil & Gas

Application

Key Capabilities

Utilities

Application

Key Capabilities

Chemical Processing

Key Capabilities

Trusted Across Industries

1,000+ companies across mining, power generation, oil & gas, chemical processing, pharmaceutical, and marine industries rely on FluidFlow for gas compressible flow system design.

Advanced Features

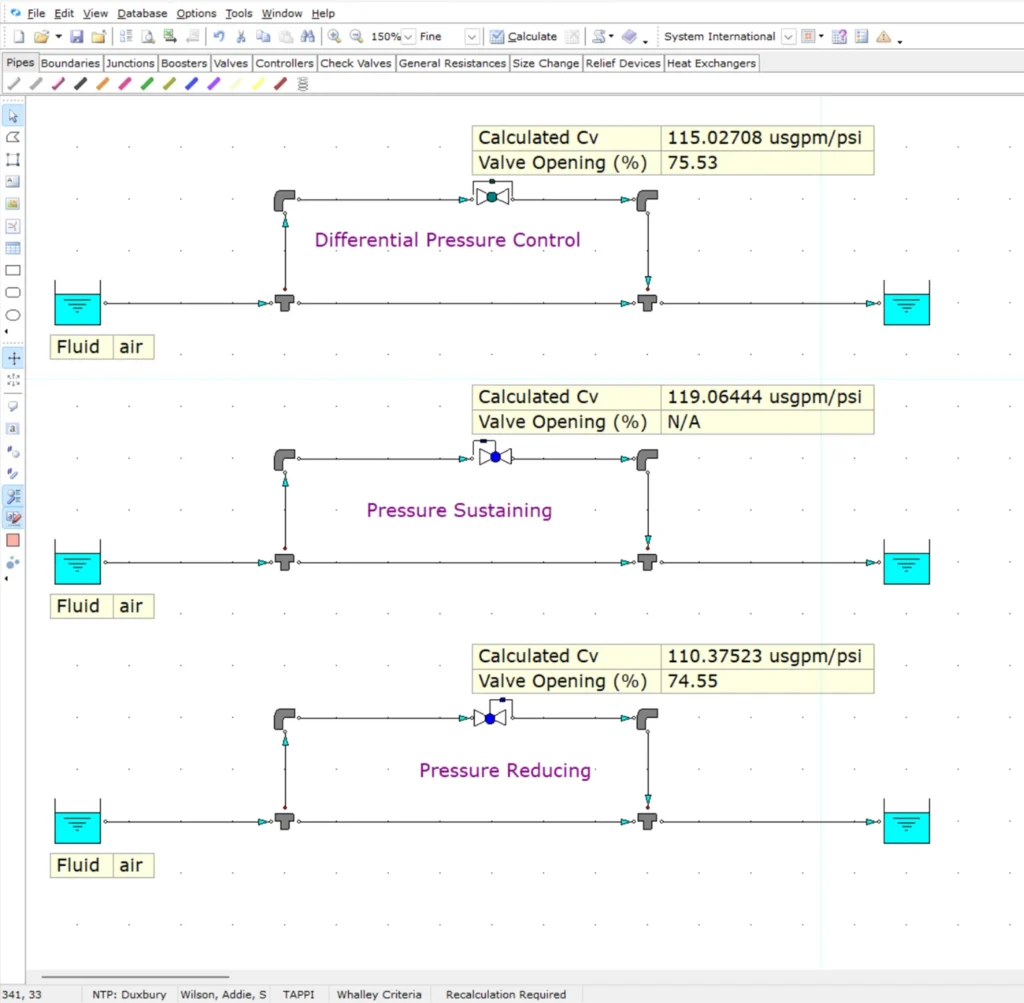

Control Valve Sizing and Analysis

- Size and back‑calculate control valves for gas service using industry‑standard methods, checking Cv, travel, and operating range to avoid operational issues, noise, and instability.

Professional Integration

- Custom reports with pressure profiles and design summaries.

- CAD PCF import from SmartPlant 3D, CADWorx, SolidWorks. Exports to PDF/Excel.

Experience FluidFlow Today

What’s Included in your Free Trial:

Full Professional Features

Access to all simulation modules and advanced tools

14 full days

Plenty of time to test with your real projects

Sample Projects Included

Pre-built examples to get you started immediately

Live Support During Trial

Get help from our engineering team via chat and email