7 Jul, 2020

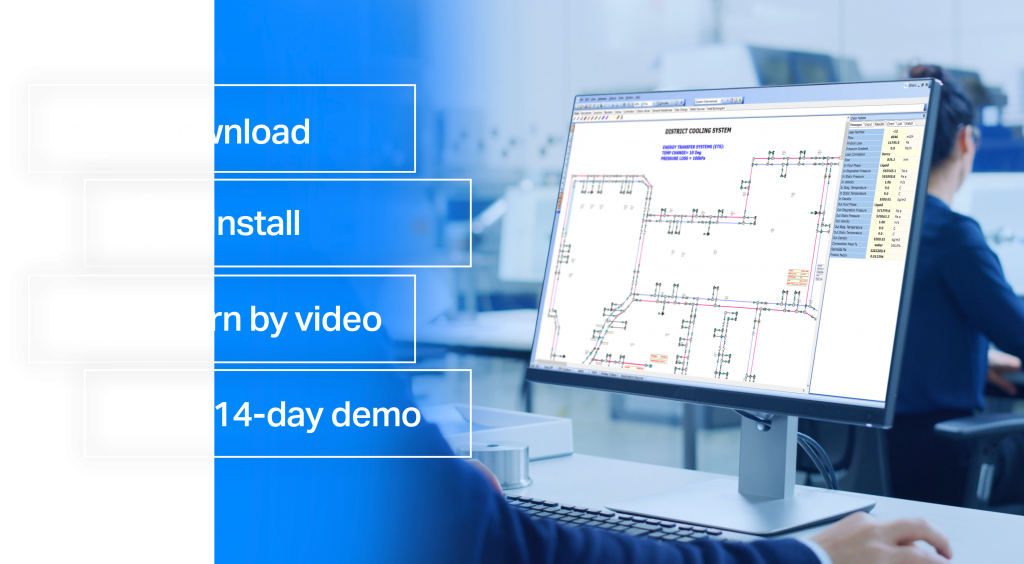

Complete Pipe Flow

Simulation Software

Model, design or analyse any

liquid, gas, two-phase, slurry or

non-Newtonian pipe flow system

from a single software solution.

Toll free: +1 888 711 3051 Worldwide: +44 28 7127 9227 Login

Spreadsheet based piping calculations are often error prone. FluidFlow eliminates such errors and helps you design efficient and reliable plant using correctly sized equipment. Comprehensive fluid and equipment databases allow you to accurately design, analyze or troubleshoot any pipe flow system

7 Jul, 2020

May 19th,2020

May 21st,2019

Get full feature access to our software, available for 14 days from installation.

Start your free trial