Home » Case Studies » Deltamarin

Deltamarin is a ship design, offshore engineering, and construction group operating in the marine and offshore industries worldwide. Services offered include the full range of consulting, design and engineering as well as procurement, construction, and installation. All phases and all disciplines in new-building and conversion projects as well as project management and operational support are covered.

Deltamarin’s customers include major international ship owners, offshore contractors, shipyards, equipment and system suppliers. The Group employs around 400 experts in its own and associated companies located in Europe and Asia.

https://deltamarin.com/

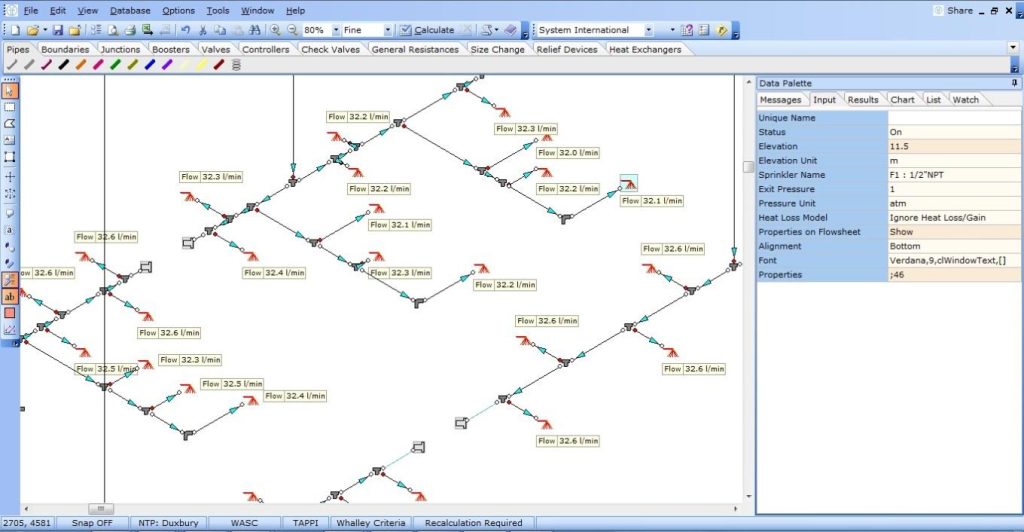

The main purpose of the project was to design and dimension a cooling system for chemical tanker propylene oxide piping. Propylene oxide is a volatile liquid which is why the propylene oxide cargo piping has to be cooled during the load and offload. This system consists of 185 sprinkler nozzles, 923 M of pipework, and associated ancillary fittings. A part-plan overview of the system is provided below in Figure 1.

To design and dimension a cooling system for chemical tanker propylene oxide piping.

The balancing of the flow between the sprinkler nozzles.

Arranging the system without pressure reducing valves.

The cooling system had to comply with the US Coast Guard rules (46 CFR 153.530 – Special requirements for alkylene oxides). Propylene oxide cargo piping had to be covered with a uniform water spray of 0.175 l/m2 sec. The system was arranged with the sprinkler nozzles and total water flow in the system was defined by calculating the sprinkler nozzle protected area with required water spray. Calculated flow in each nozzle was 31.5 l/min.

Aleksi Aurivuo

Deltamarin

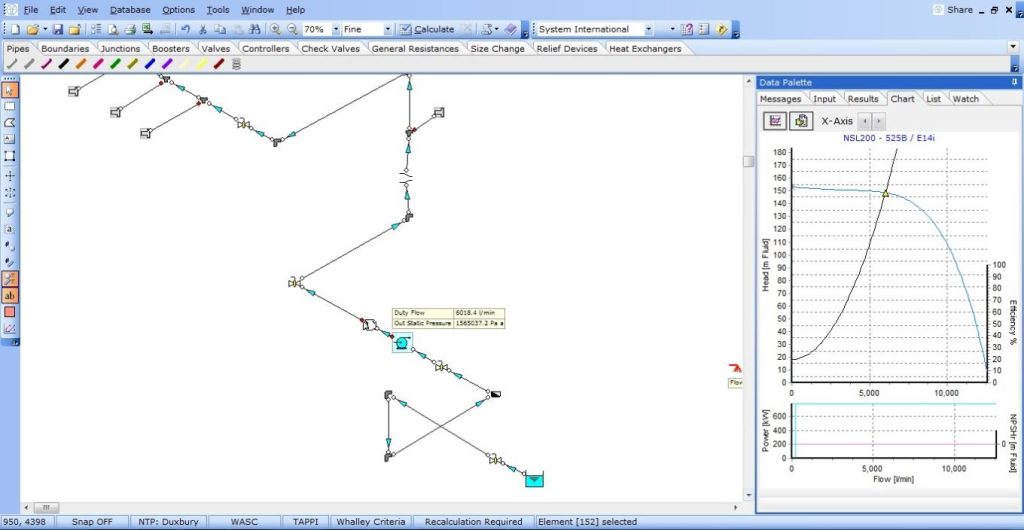

Deltamarin’s engineers utilized FluidFlow to design the system and develop an understanding of the plant operating performance. Through detailed modelling, the team was able to identify any potential performance issues, size the circulating pump, consider line velocities, and size the network of pipes.

Streamline your design process and optimize performance with FluidFlow.

© 2025 Flite Software NI Ltd. All rights reserved.